Basic Forest Fire Suppression Course - Online Lessons

LESSON 4 - FOREST FIRE SUPPRESSION TOOLS

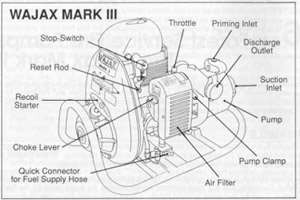

Canadian wildland fire suppression agencies currently use the Wajax Mark 3 as the pump of choice for delivering water. It is a low volume/high pressure pump capable of delivering 300PSI. High pressure is a requirement for delivering water to separate fuels on the surface and to provide penetrating power for burning material in the ground fuel layer below the surface.

Starting & Warmup Procedure:

- Connect fuel line to tank and pump

- Turn fuel line connector at the base of the pump until secure

- Vent the fuel tank

- Connect discharge hose (1½ inch forestry hose) to the discharge outlet on the pump.

- Connect a foot valve to an intake (suction) hose and drop into a sufficient water supply. The valve cannot come in contact with small loose material that can end up inside the pump and cause internal damage. Place the valve inside a bucket or use any other means to avoid contact with the bottom.

- If you can, fill the intake hose with water and connect to the pump. Once this connection has been made, ensure that a hose wrench is used to tighten the connection and prevent air from entering the pump. The pump could loose prime and shut off if this is not done.

- Open drain cock on primer line

- Pump primer until you get a steady stream of water

- Close drain cock on primer line

- Move throttle (located on the top of the pump) to start and warm up position (2 -3 clicks)

- Ensure toggle (located on top of the pump) switch is in the on position

- Ensure cut out (located at the bottom of the pump) switch is pushed in

- If the pump is cold or has not run for a while move the choke (located on the side of the pump) to the start position. Most pumps are clearly marked, if not, move the switch toward the operator

- Pull the starter cord until the pump begins to run

- Once running smoothly move the choke to the run position. This should be done as soon as you are sure that the pump will continue to run

- The pump will “flood” easily if the choke is left in the start position before starting (too much fuel in the cylinder before starting). Make sure the choke is moved to the run position right away

- Let pump warm up keeping it at an idle for 2 minutes before increasing the throttle. It is very important to follow the same procedure when shutting down the pump. Slowly reduce throttle speed and allow a cool down period before shutting the pump off. This is extremely important because of the different kinds of metal which will heat up or cool down at different rates and could break in the process leaving the pump inoperable.

* Always use regular fuel mixed with Castrol Super 2-Stroke oil; mix at a 24:1 ratio. (24 litres of fuel mixed with 1 litre of oil)

* Warm-up is very important

Once the pump has been warmed up properly you may use it. This is as high pressure pump and requires a firm grip when using the nozzle. Most pump crews will have someone at the pump ensuring a smooth operation. Sometimes the “pump operator” will stay for the duration of use, at times they may stay for the first 20 minutes or so to ensure it will operate well.

The choice of nozzle depends on the type of fire activity. Small, low intensity surface fires are easily put out using a fog nozzle which creates a spray pattern of your desire.

For high intensity surface fires or material that is burning below the surface you should use a barrel (straight) nozzle which is able to deliver water over a distance on heat sources that are too hot to get close to or can "dig" into the soil for good penetration.

The operation of any pump is not complete without the addition of a tool box that is required to maintain the smooth operation of the pump and hose line. Together the following items make up a complete package called a pump unit and all pieces are required in order to do the job.

- Pump

- Tool box

- Intake hose (suction line)

- 1 ½ inch Forestry discharge hose

- Gas container

Standard barrel nozzles – Used for the purpose of directing water at the end of a hose line. They provide a single stream of high pressure water that can be used for the purpose of extinguishing flames from a distance (± 20 meters) or creating a fuel break around a fire. Fuels need to be separated to slow or stop fire spread and even a break of a few centimeters is sometimes all that`s required. All barrel nozzles are equipped with three tips which can increase water pressure, if a smaller diameter tip is used (In the event that pressure is lost).

Fog nozzle – Can be used for the same purpose as a barrel nozzle with less pressure. The unique feature of this nozzle is that it has an adjustable end which will provide a straight stream or a widely scattered spray which may be better in certain fuel types (grass or other fine fuels during early spring) Fuels in the early spring are much easier to put out and because the ground conditions are usually wet, the need for digging power in grass is not required.

Hose Strangler – Is used for restricting water flow through a charged (water flow in the hose) hose line. This equipment is required when additional hose or other pieces of equipment are added to the system. While using the strangler, tremendous pressure is exerted on the hose and caution must be taken to ensure the safety of the operator.

- Both hands must be used to control the pressure.

- Keep one foot in front of the device to prevent it from sliding up the hose line in the direction of flow.

- Make sure that the inserted hose is well back from the front of the strangler. If the hose slides toward the front, two small cuts will appear in the hose and if the hose is weak, it could rupture. Communications must take place between the nozzle person and the strangler operator so that each knows where the pressure is on the line.

Hose wrench – Used to tighten up the intake hose connection at the pump.

Spare spark plugs and other repair tools

Gas line – Used to connect pump to gas can

Foot valve – Kept in the tool box and placed on the intake hose when required.

Water Thief – An adaptor which is be placed between two lengths of discharge hose and can siphon water from the main line for the purpose of filling back tanks or adding 3/4 inch patrolling hose.

Gated “Y” – An adapter which is added to a length of discharge hose and is used for the purpose of adding another hose line.

Tandem coupling – If there is a significant drop in water pressure with only one pump providing water, a second or more can be added to the line which should increase the water pressure at the nozzle. The tandem coupling is placed on the intake connection of the added pump and the pump is then connected to the discharge hose at both ends. Water is forced directly into the pump without the need of setting up a relay tank to draw from.

Other pieces of equipment found in the tool box include: pliers, screw drivers, spare rope, adaptors, hose repair kits, spare rubber inserts.